Branding and decoration techniques

Everything you need to know about different decoration techniques for various promotional products and apparel

What can we do to make your swag stand out?

Branded swag is more than just promotional stuff. It’s an integral part of your brand and your corporate culture. With different decoration techniques, you can create a really unique look, stay true to classics, or bring a luxurious feel even to the simplest of items. With over 25 years of experience, we know everything about swag decorating techniques and will be happy to help you design your perfect branded collection!

Decoration techniques in a nutshell

For apparel and bags

- Digital direct-to-garment (DTG)

- Screen printing

- Pad printing

- Dye sublimation

- Heat transfer

Yes, it is possible to do laser engraving on apparel. The only limitation is that this method doesn’t work with 100% natural fabrics.

- Deboss

- Epoxy dome

- HXD (High Definition with Extra Dimension)

- Classic embroidery

- 3D embroidery

For hardgoods

- Pad printing

- Full color digital

- Dye sublimation

- Screen printing

- Heat transfer

- Metal

- Ceramics

- Acrylic

- Deboss (on journal covers)

- Laser etching

- Chemical etching

Imprint Methods

Digital printing

DTG – Direct to Garment

DTG is a special process of digital printing on textiles that uses special aqueous textile inks and inkjet printers designed to hold the garment in place under the moving printing head.

Allows for sharp, high-resolution images (including photos) printed directly on apparel.

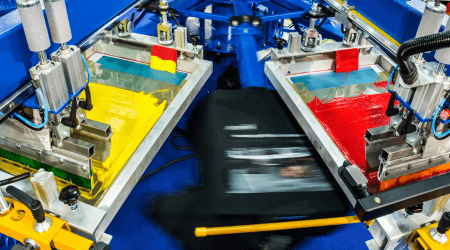

Screen printing

Screen printing is a method of imprinting images onto a flat surface by pushing ink through a stencil on a mesh screen.

Screen printing has limitations on the number of colors used in the design since each color requires its-own stencil. It won’t work for photorealistic images.

The complexity of the design and the number of colors will impact the price.

Screen printing is typically used on textiles, but with special inks or paints, it can be used on metal, plastic, wood, and sometimes glass.

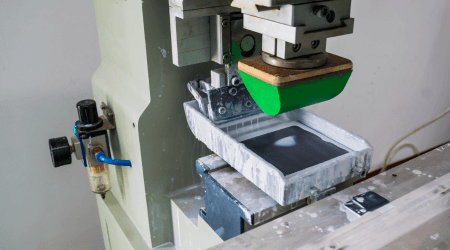

Pad printing

Pad printing is a method of transferring an image with a soft silicone pad from a printing plate onto an object. It is perfect for printing on non-flat surfaces since the pad is soft enough to mimic the shape of the receiving object.

This imprint method is very limited in the number of colors used in the design. The most economical and most common in the swag industry is a 1-color imprint.

Dye sublimation

Creates a nearly-permanent high-resolution, full-color print because the dyes are infused into a surface rather than being applied on top.

The mirrored image is first printed on specially coated transfer paper and then transferred onto the flat object with a heat press.

When used on textiles, this method creates a faded, “worn” look.

Works best on polyester and polymer-coated surfaces.

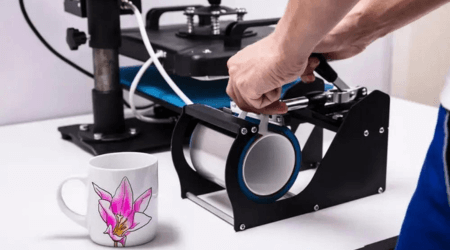

Heat transfer

The vinyl heat transfer method uses the designs cut out of the colored vinyl film and transferred onto the surface with a heat press.

The printed heat transfer method uses the designs printed on transfer paper and applied onto the surface with a heat press.

Other branding methods

Embroidery

Embroidery is a decoration method that involves needles and thread. It is durable and vibrant and gives your swag a luxury feel. The density of the final embroidery is defined by a stitch count which depends on design and material. Consult your account representative on the best look for your product.

3D embroidery or puff embroidery is raised above the surface. The “puff” effect is achieved by a piece of foam that is placed behind the thread.

Laser engraving & etching

Using laser is one of the most precise methods for logo imprinting and can be used for small, highly detailed designs. The effect is achieved by melting and removing (engraving) or raising (etching) the surface material. This decoration method doesn’t allow for any color. Laser techniques can be used for apparel (except white) if the fabric contains enough polyester.

HXD & epoxy dome

HXD (High Definition with Extra Dimension) is the most durable and versatile decoration method on the market. The 3D polymer emblem is produced with laser accuracy and can be adhered to almost any product. This method works for small detail and complex design.

Epoxy dome is a thick clear coat of high-gloss polyurethane applied over a printed design creating a 3D emblem that can be adhered to a promotional product.

Deboss

This decoration method uses heat and pressure to leave an imprint of the design on soft materials like fabric, paper, leather/faux leather. Because the design is pressed directly into materials without any color, debossing is used to achieve an elegant monochromatic look.